Preliminary indications

WE strongly advise against connecting 2 or more WW-10 panels

in series, in order to avoid pressure losses that are too high, and

problems with bleeding out the air.

If the panel is put in a position in which it is not possible to

connect the WW-10 panel to the supply line directly, use an

DN10 sleeve and a piece of DN10 pipe to form the extension.

In order to avoid condensation forming on the mirror when

using the shower or bath tub, a WW-10 panel can be positioned

behind the mirror. However, what must be assured is that the

mirror must sit perfectly flat on the rendered wall.

Installation

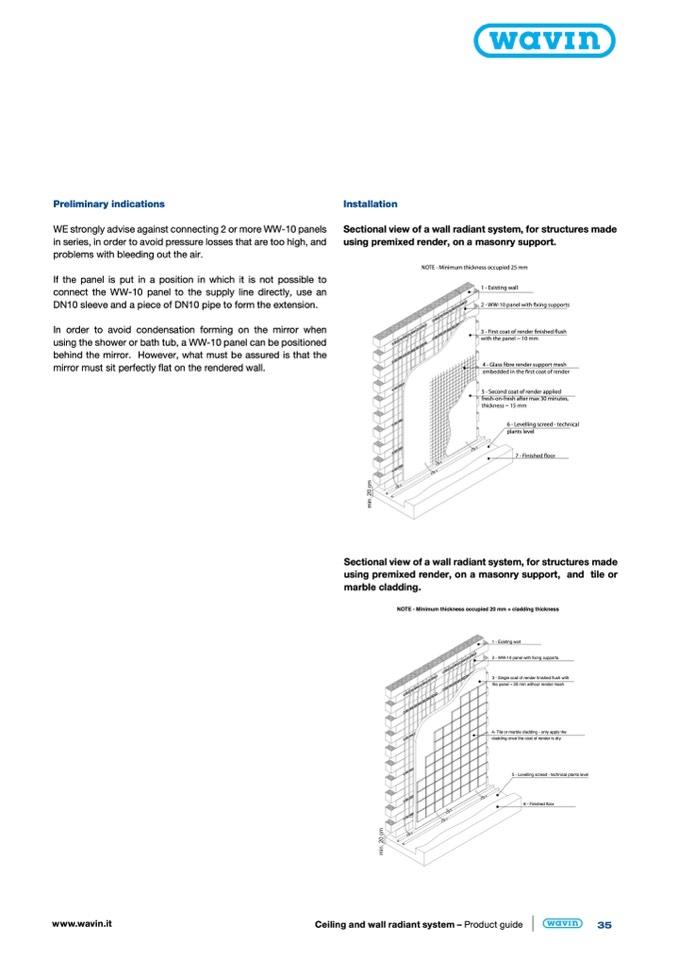

Sectional view of a wall radiant system, for structures made

using premixed render, on a masonry support.

NOTE - Minimum thickness occupied 25 mm

1 - Existing wall

2 - WW-10 panel with fixing supports

3 - First coat of render finished flush

with the panel ~ 10 mm

4 - Glass fibre render support mesh

embedded in the first coat of render

5 - Second coat of render applied

fresh-on-fresh after max 30 minutes,

thickness ~ 15 mm

6 - Levelling screed - technical

plants level

7 - Finished floor

Sectional view of a wall radiant system, for structures made

using premixed render, on a masonry support, and tile or

marble cladding.

NOTE - Minimum thickness occupied 20 mm + cladding thickness

1 - Existing wall

2 - WW-10 panel with fixing supports.

3 - Single coat of render finished flush with

the panel ~ 20 mm without render mesh

4- Tile or marble cladding - only apply the

cladding once the coat of render is dry

5 - Levelling screed - technical plants level

6 - Finished floor

www.wavin.it

Ceiling and wall radiant system – Product guide

35