Preliminary indications

WE strongly advise against connecting 2 or more WW-10 panels

in series, in order to avoid pressure losses that are too high, and

problems with bleeding out the air.

If the panel is put in a position in which it is not possible to

connect the WW-10 panel to the supply line directly, use an

DN10 sleeve and a piece of DN10 pipe to form the extension.

Installation

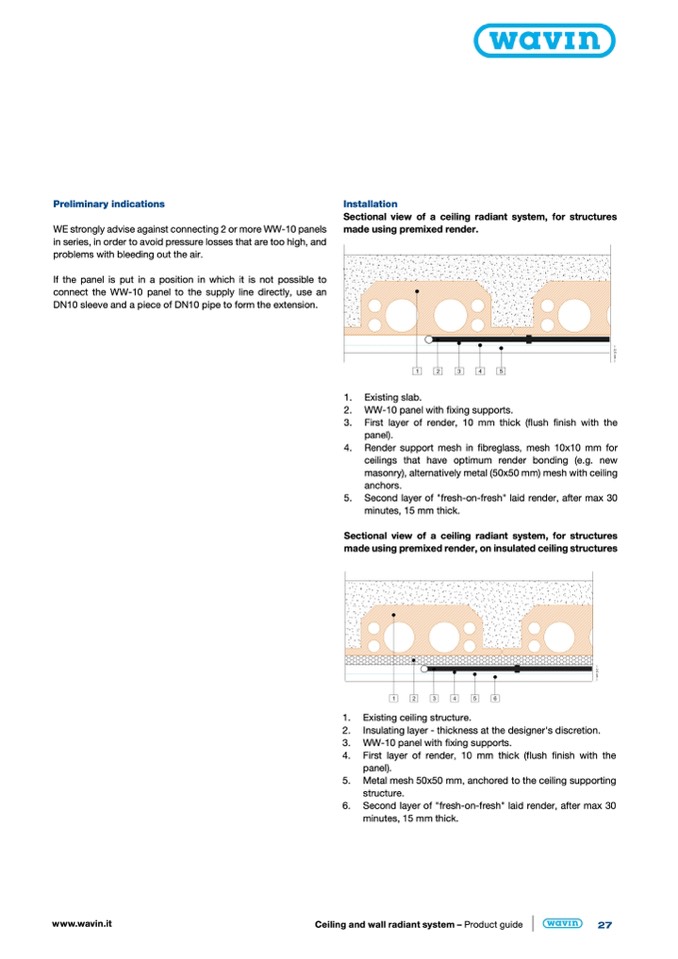

Sectional view of a ceiling radiant system, for structures

made using premixed render.

www.wavin.it

Ceiling and wall radiant system – Product guide

27

1. Existing slab.

2. WW-10 panel with fixing supports.

3. First layer of render, 10 mm thick (flush finish with the

panel).

4. Render support mesh in fibreglass, mesh 10x10 mm for

ceilings that have optimum render bonding (e.g. new

masonry), alternatively metal (50x50 mm) mesh with ceiling

anchors.

5. Second layer of "fresh-on-fresh" laid render, after max 30

minutes, 15 mm thick.

Sectional view of a ceiling radiant system, for structures

made using premixed render, on insulated ceiling structures

1. Existing ceiling structure.

2. Insulating layer - thickness at the designer's discretion.

3. WW-10 panel with fixing supports.

4. First layer of render, 10 mm thick (flush finish with the

panel).

5. Metal mesh 50x50 mm, anchored to the ceiling supporting

structure.

6. Second layer of "fresh-on-fresh" laid render, after max 30

minutes, 15 mm thick.