Installation - Hydraulic connections

In order to optimise the system's performance, we recommend

connecting the panels using the Tichelmann system (with re-

verse return), thereby facilitating self-balancing of each individ-

ual outgoing circuit of the manifold.

The sum of the lengths of the panels in series must not differ

from the lengths of the individual panels by more than 10%

within the same circuit.

Installation - Structure and cladding

In order to obtain a radiant system with the maximum heat and

structural performance, after taking the preliminary precautions

listed above, it is best to follow this procedure:

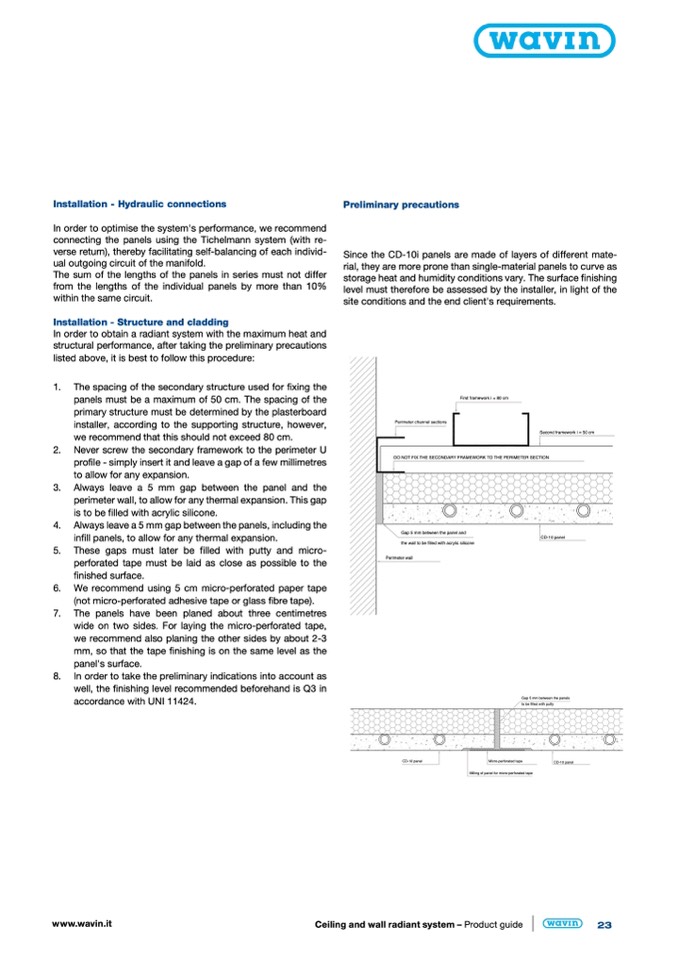

1. The spacing of the secondary structure used for fixing the

panels must be a maximum of 50 cm. The spacing of the

primary structure must be determined by the plasterboard

installer, according to the supporting structure, however,

we recommend that this should not exceed 80 cm.

2. Never screw the secondary framework to the perimeter U

profile - simply insert it and leave a gap of a few millimetres

to allow for any expansion.

3. Always leave a 5 mm gap between the panel and the

perimeter wall, to allow for any thermal expansion. This gap

is to be filled with acrylic silicone.

4. Always leave a 5 mm gap between the panels, including the

infill panels, to allow for any thermal expansion.

5. These gaps must later be filled with putty and micro-

perforated tape must be laid as close as possible to the

finished surface.

6. We recommend using 5 cm micro-perforated paper tape

(not micro-perforated adhesive tape or glass fibre tape).

7. The panels have been planed about three centimetres

wide on two sides. For laying the micro-perforated tape,

we recommend also planing the other sides by about 2-3

mm, so that the tape finishing is on the same level as the

panel's surface.

8. In order to take the preliminary indications into account as

well, the finishing level recommended beforehand is Q3 in

accordance with UNI 11424.

Preliminary precautions

Since the CD-10i panels are made of layers of different mate-

rial, they are more prone than single-material panels to curve as

storage heat and humidity conditions vary. The surface finishing

level must therefore be assessed by the installer, in light of the

site conditions and the end client's requirements.

First framework i = 80 cm

Perimeter channel sections

Second framework i = 50 cm

DO NOT FIX THE SECONDARY FRAMEWORK TO THE PERIMETER SECTION

Perimeter channel sections

Gap 5 mm between the panel and

Second framework i = 50 cm

First framework i = 80 cm

DO NOT FIX THE SECONDARY FRAMEWORK TO THE PERIMETER SECTION

CD-10 panel

the wall to be filled with acrylic silicone

Perimeter wall

Perimeter wall

Gap 5 mm between the panel and

the wall to be filled with acrylic silicone

CD-10 panel

Gap 5 mm between the panels

to be filled with putty

Gap 5 mm between the panels

to be filled with putty

CD-10 panel

Micro-perforated tape

Milling of panel for micro-perforated tape

Micro-perforated tape

Milling of panel for micro-perforated tape

CD-10 panel

CD-10 panel

CD-10 panel

www.wavin.it

Ceiling and wall radiant system – Product guide

23