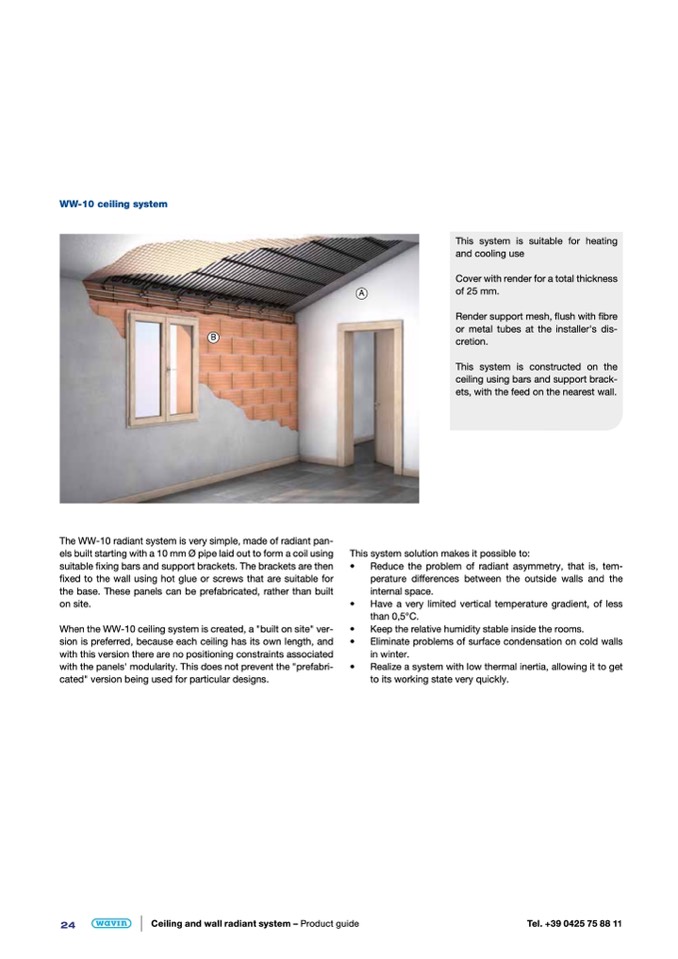

WW-10 ceiling system

The WW-10 radiant system is very simple, made of radiant pan-

els built starting with a 10 mm Ø pipe laid out to form a coil using

suitable fixing bars and support brackets. The brackets are then

fixed to the wall using hot glue or screws that are suitable for

the base. These panels can be prefabricated, rather than built

on site.

When the WW-10 ceiling system is created, a "built on site" ver-

sion is preferred, because each ceiling has its own length, and

with this version there are no positioning constraints associated

with the panels' modularity. This does not prevent the "prefabri-

cated" version being used for particular designs.

This

•

•

•

•

•

system solution makes it possible to:

Reduce the problem of radiant asymmetry, that is, tem-

perature differences between the outside walls and the

internal space.

Have a very limited vertical temperature gradient, of less

than 0,5°C.

Keep the relative humidity stable inside the rooms.

Eliminate problems of surface condensation on cold walls

in winter.

Realize a system with low thermal inertia, allowing it to get

to its working state very quickly.

B

A

This system is suitable for heating

and cooling use

Cover with render for a total thickness

of 25 mm.

Render support mesh, flush with fibre

or metal tubes at the installer's dis-

cretion.

This system is constructed on the

ceiling using bars and support brack-

ets, with the feed on the nearest wall.

24

Ceiling and wall radiant system – Product guide

Tel. +39 0425 75 88 11